The jewelry manufacturing process is a blend of creativity, precision engineering, skilled craftsmanship, and modern technology. From a simple idea sketched on paper to a finished piece worn with pride, every stage plays a vital role in determining quality, durability, and beauty.

Whether you are a jewelry brand owner, wholesaler, retailer, or someone planning to start your own venture, understanding the jewelry manufacturing process helps you make better design, sourcing, and quality decisions. Trusted manufacturers like eongems support brands with end-to-end production solutions, making it easier to convert ideas into market-ready jewelry while maintaining consistent quality.

This guide explains the complete process step by step, covering traditional techniques as well as modern manufacturing practices followed by professional manufacturers like eongems.

Introduction to the Jewelry Manufacturing Process

The jewelry manufacturing process involves multiple interconnected steps that transform raw metals and gemstones into wearable art. Each stage requires attention to detail, skilled labor, and strict quality checks to ensure consistency and excellence.

Modern manufacturers combine traditional handcrafting methods with advanced technologies like CAD design and precision casting. This balance allows brands to create both custom pieces and large production runs without compromising quality.

Concept Development and Design Planning

Every piece of jewelry starts with an idea. This initial phase defines the overall direction of the design.

Design planning includes

- Understanding market trends

- Identifying the target audience

- Selecting jewelry type such as rings, necklaces, bracelets, or earrings

- Deciding on gemstone usage and metal type

Many brands align their collections with current fashion movements to stay relevant in competitive markets. Insights from the latest trends in jewellery design help manufacturers determine preferred shapes, finishes, and gemstone combinations. Design teams at eongems blend these trend insights with client branding requirements to create designs that are both stylish and production-efficient.

At this stage, manufacturers like eongems work closely with clients to refine concepts before moving into technical design.

CAD Designing and Prototyping

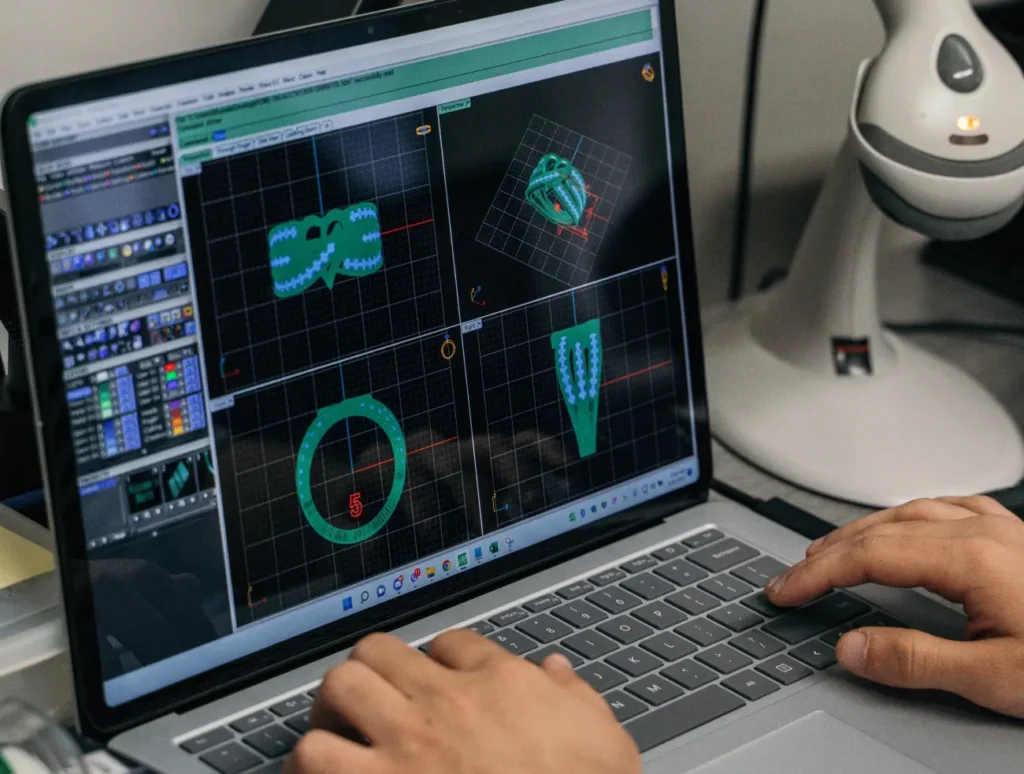

Once the concept is finalized, it moves into digital development using Computer Aided Design.

CAD design allows

- Precise measurements

- Accurate stone placement

- Structural integrity testing

- Faster design revisions

A digital model ensures that the design can be manufactured efficiently while minimizing material wastage. Prototyping often follows, using resin or wax to create a physical sample for evaluation.

This step is critical in the jewelry manufacturing process as it bridges creativity with manufacturability.

Selection of Metals and Gemstones

Material selection defines the value, durability, and appeal of jewelry.

Metal Selection

Common metals include

- Gold in yellow, white, and rose variations

- Sterling silver

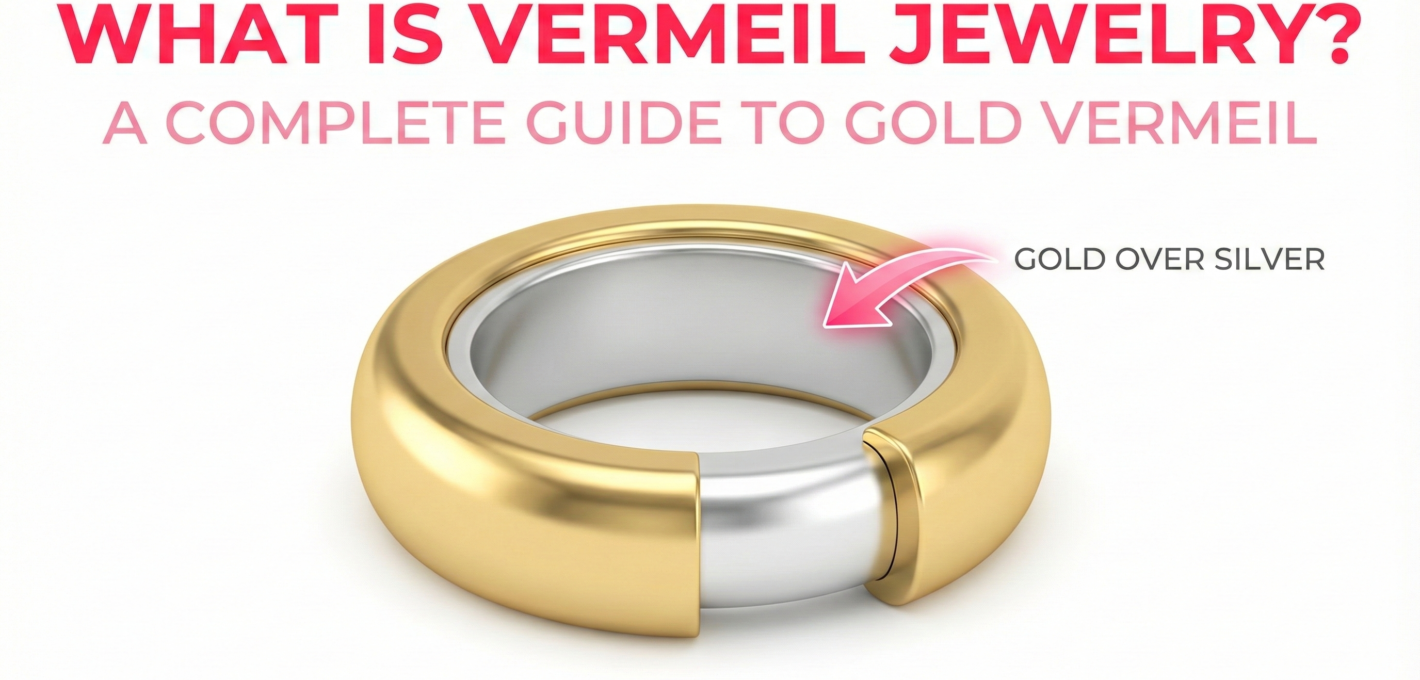

- Vermeil and platinum

Each metal has different properties related to hardness, color, and maintenance. For example, understanding types of gold white yellow and rose gold helps in choosing the right metal for durability and aesthetics.

Gemstone Selection

Gemstones are chosen based on

- Hardness and durability

- Color and clarity

- Market demand

Manufacturers often guide clients in selecting gemstones based on durability, pricing, and target market expectations. Understanding the difference between precious vs semi precious gemstones allows brands to balance luxury appeal with commercial viability. This strategic gemstone selection plays a key role in long-term customer satisfaction and resale value.

Wax Model Creation

The approved CAD design is converted into a wax model. This model serves as the foundation for casting.

Wax models are created using

- 3D printing technology

- Hand carving for intricate designs

Multiple wax models may be attached to a tree structure to cast several pieces simultaneously, improving production efficiency.

Wax modeling is one of the most crucial steps in the jewelry manufacturing process because any flaw at this stage transfers to the final piece.

Casting Process

Casting transforms the wax model into metal jewelry.

The most commonly used technique is lost wax casting, where

- Wax models are encased in a plaster mold

- Heat melts the wax, leaving a cavity

- Molten metal is poured into the mold

Once cooled, the mold is broken to reveal the raw metal piece. This method ensures high accuracy and is widely used for gold, silver, and platinum jewelry.

Manufacturers producing large volumes rely on casting techniques to maintain design consistency and cost efficiency. This is especially important for brands supplying international markets, where uniform quality is essential. Experienced exporters such as an India silver jewelry exporter to Finland follow strict production and finishing standards to meet global expectations.

Stone Setting Techniques

After casting, gemstones are carefully set into the metal framework.

Common stone setting methods include

- Prong setting

- Bezel setting

- Pave setting

- Channel setting

Stone setting requires precision and experience, especially when working with diamonds or fragile gemstones. The choice between stone types also impacts setting techniques and long-term durability. Many buyers today compare natural diamonds vs lab grown diamonds to evaluate factors such as cost, sustainability, and brilliance. Professional manufacturers adjust stone setting methods accordingly to ensure secure placement and lasting performance.

Improper stone setting can compromise durability, making this a highly skilled stage in the jewelry manufacturing process.

Polishing and Surface Finishing

Polishing enhances the beauty of jewelry and prepares it for final presentation.

This stage includes

- Filing rough edges

- Buffing to achieve shine

- Applying matte, high polish, or textured finishes

Surface finishing not only improves appearance but also removes minor imperfections from earlier stages.

For jewelry meant for long-term wear, finishing impacts comfort and skin compatibility, especially for people with sensitive skin.

Quality Control and Inspection

Quality control ensures every piece meets industry and client standards.

Inspection checks include

- Metal purity verification

- Stone security testing

- Weight and dimension accuracy

- Visual symmetry and finishing

Reputable manufacturers like eongems follow multi-level inspections before approving jewelry for hallmarking or shipping.

Quality assurance is essential in the jewelry manufacturing process to maintain brand reputation and reduce returns.

Hallmarking and Certification

Hallmarking certifies the purity of precious metals.

Depending on the market, jewelry may require

- Gold or silver hallmark stamps

- Diamond grading certificates

- Country-specific compliance marks

This step builds trust and transparency with buyers, especially in international trade and wholesale distribution.

Packaging and Branding

Once approved, jewelry is prepared for presentation.

Packaging includes

- Protective wrapping

- Branded boxes

- Care instructions

Well-designed packaging enhances perceived value and supports brand recognition. This is particularly important for businesses planning resale or exports, as professional packaging reflects manufacturing credibility.

Sustainable and Ethical Jewelry Manufacturing

Modern consumers increasingly value ethical practices.

Sustainable jewelry manufacturing focuses on

- Responsible sourcing of metals and gemstones

- Reduced environmental impact

- Fair labor practices

Ethical production is no longer optional. It is a competitive advantage for manufacturers and brands looking to build long-term trust.

Why Understanding the Jewelry Manufacturing Process Matters

Knowing the jewelry manufacturing process helps you

- Communicate better with manufacturers

- Control production costs

- Ensure consistent quality

- Make informed material choices

For entrepreneurs planning long-term growth, understanding production workflows is essential before you start your own jewelry business. Knowledge of manufacturing timelines, sourcing strategies, and quality benchmarks helps avoid costly mistakes and supports smooth brand scaling when working with professional manufacturers.

Manufacturers like eongems simplify this journey by offering end-to-end solutions from design to final delivery.

FAQs

The jewelry manufacturing process typically takes 2 to 6 weeks, depending on design complexity, metal type, gemstone availability, and order volume. Custom or handcrafted jewelry may take longer than mass-produced pieces, while CAD-based manufacturing helps reduce turnaround time without compromising quality.

Handmade jewelry manufacturing relies heavily on artisan skills and manual techniques, making each piece unique. Machine-made jewelry uses CAD, casting, and automation for consistency and scalability. Many modern manufacturers combine both methods to balance craftsmanship, precision, and cost efficiency.

Yes, the jewelry manufacturing process varies based on material. Gold requires precise alloying and purity control, silver needs special oxidation prevention during finishing, and diamond jewelry involves advanced stone setting and certification steps. Each material follows a customized workflow to ensure durability and quality.

A professional jewelry manufacturer should provide metal purity hallmarking, gemstone authenticity certificates, and quality assurance documentation. For diamonds, grading reports are essential, while export jewelry may require additional compliance and international standards certification.

Yes, the jewelry manufacturing process can be fully customized for private label brands. This includes custom designs, exclusive molds, branded packaging, metal selection, gemstone sourcing, and even personalized hallmarking, making it ideal for startups and established jewelry businesses.

Quality control is critical in the jewelry manufacturing process as it ensures metal purity, secure stone setting, accurate weight, and flawless finishing. Multiple inspection stages reduce defects, improve customer satisfaction, and protect brand reputation, especially in wholesale and export jewelry production.

Final Thoughts

The jewelry manufacturing process is a carefully structured journey that combines art, science, and craftsmanship. Each step, from concept design to final polishing, plays a crucial role in creating jewelry that lasts generations.

Whether you are a designer, retailer, exporter, or aspiring entrepreneur, partnering with an experienced manufacturer ensures quality, transparency, and scalability. By working with eongems, brands gain access to modern manufacturing facilities, ethical sourcing, and global supply capabilities that support long-term success. With expert guidance, modern technology, and ethical practices, companies like eongems help transform ideas into exceptional jewelry that stands out in global markets.

If you want to explore professional manufacturing, design consultation, or bulk production, connecting with eongems is a smart step toward building a trusted jewelry brand.