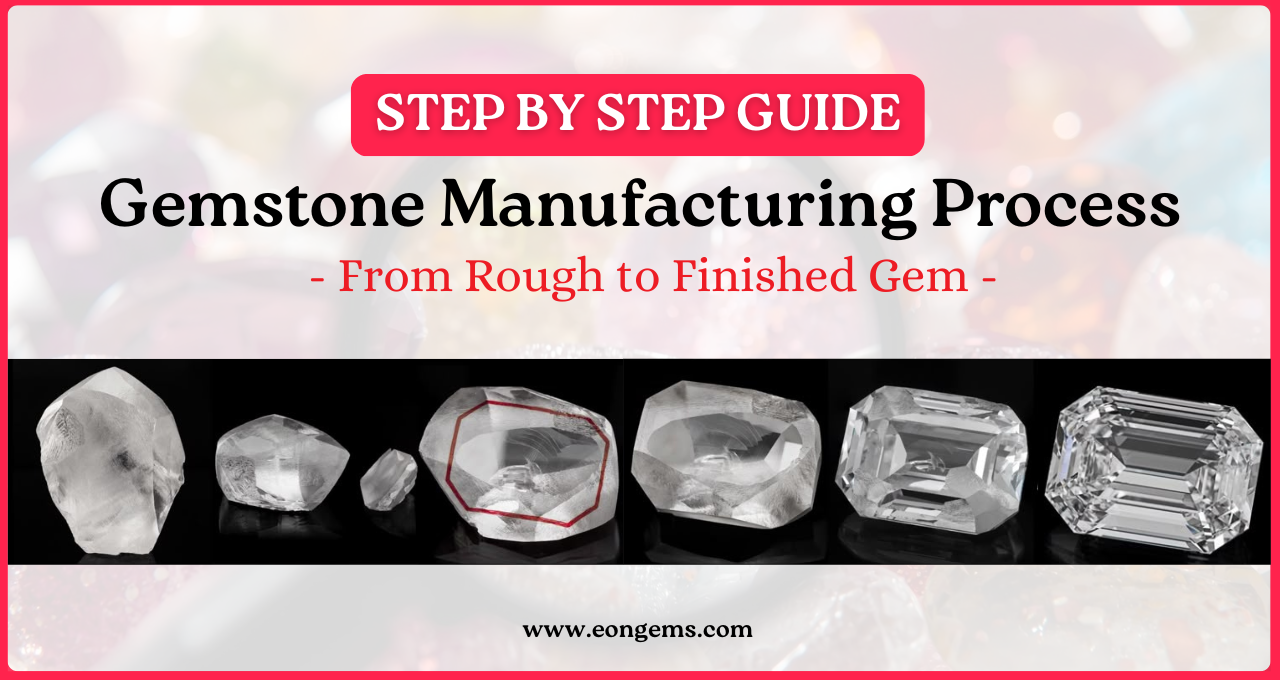

The gemstone manufacturing process turns rough, unshaped mineral crystals into polished gemstones ready for jewelry setting. While every gemstone type has its own personality, most follow a similar journey. It starts with careful selection of rough material, then moves through planning, cutting, shaping, polishing, grading, and final quality checks.

If you are a buyer, a jewelry brand, or a wholesaler, understanding this process helps you judge quality, pricing, and authenticity. A well manufactured gemstone does not just look beautiful, it also performs better in a setting, resists chipping, and keeps its brilliance for years. For a quick look at available stones and categories, explore the Gemstones collection.

What gemstone manufacturing really means

Gemstone manufacturing is the controlled production workflow used to convert rough stones into finished gems. This includes both precision craftsmanship and technical decisions, like choosing the best cut for weight retention, deciding whether a stone should be faceted or made into a cabochon, and ensuring calibration for standard jewelry sizes.

The gemstone manufacturing process also covers sorting, matching, and consistency steps that matter in bulk orders. For example, if a brand needs fifty stones that look uniform in shade and size, the manufacturing team must select compatible rough, plan cuts carefully, and grade finished output with strict tolerance.

To understand how production usually flows from start to finish, visit the Process page and compare the workflow with the steps covered in this guide.

1. Sourcing and selecting rough gemstones

Everything begins with rough selection. This step decides the final look more than most people realize. Rough gemstones can vary in color zoning, clarity, inclusions, fractures, and crystal shape. A strong selection process reduces waste and increases finished quality.

Manufacturers evaluate rough for potential yield and risk. A stone with a stunning color may still be a poor choice if it has deep fractures in the center. Another rough piece might look average but cut into a bright, lively gem once shaped properly.

- Rough is sorted by type, size, and color range

- Obvious fractures and unstable pieces are separated early

- Yield potential is estimated to plan the best cut

- Matching lots are created for bulk orders and sets

2. Cleaning and preforming

Before cutting, rough material is cleaned and sometimes trimmed. Cleaning removes surface dirt and residue so the cutter can see true color and transparency. Preforming shapes the rough into a manageable outline. This helps reduce cutting time and improves accuracy later.

Preforming is also where a cutter starts thinking about the final design. For faceted stones, the preform may be shaped close to an oval, round, pear, or cushion outline. For cabochons, the preform is prepared to maximize smooth dome coverage and stable base thickness.

- Cleaning improves visibility of true color and clarity

- Preforming reduces waste during precision cutting

- Early shaping helps avoid stress points that cause cracking

- Orientation decisions often begin here

3. Orientation planning

Orientation is one of the most critical stages in the gemstone manufacturing process. The cutter decides how the stone will sit during cutting. This choice affects brilliance, color appearance, and durability. It also impacts how much weight is retained from the rough.

For certain gemstones, orientation matters because of optical behavior. Some gems show better color from one direction, others show phenomena like a star effect or cat eye effect only when aligned properly. Even when a stone does not have special effects, correct orientation can reduce windowing, which is when you can see straight through the gem due to poor angles.

- Best color direction is evaluated under controlled light

- Inclusions are positioned to be less visible from the face view

- Natural crystal shape is used to preserve weight where possible

- Risk areas are oriented away from thin edges and corners

4. Cutting styles, faceting vs cabochon

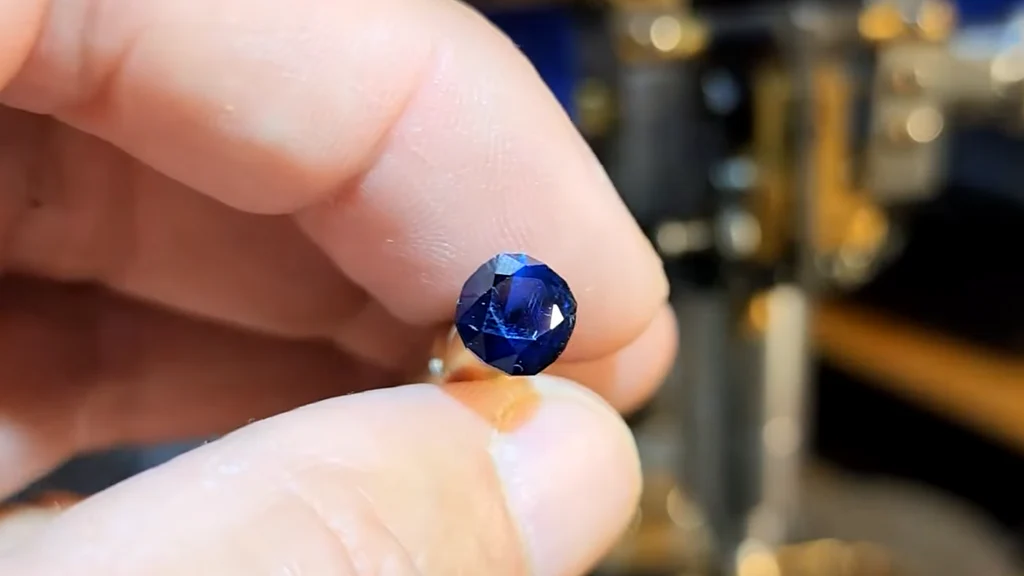

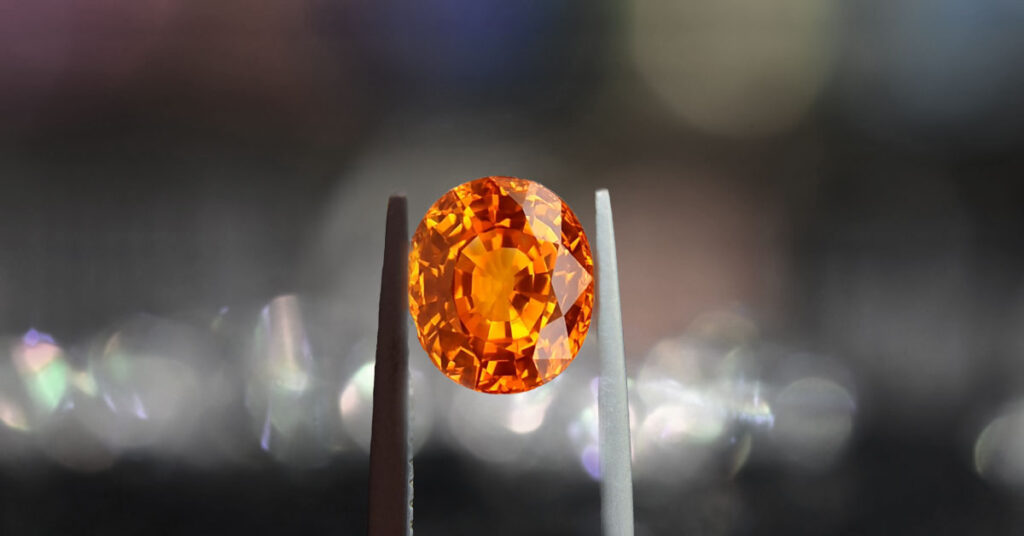

The manufacturing team chooses a cutting style based on the stone’s material, clarity, and intended jewelry design. Faceting is used to create brilliance and sparkle through precise angles. Cabochon cutting is used for stones that look best with a smooth dome, including those with visible inclusions, soft glow, or optical effects.

A faceted gemstone needs good transparency to perform well. If a gemstone is heavily included or more translucent, a cabochon may look richer and more natural. Cabochons are also common for stones like moonstone, opal, and star sapphires, where the visual effect is better without facets.

- Faceting enhances brilliance in transparent gemstones

- Cabochon cutting suits translucent stones and effect stones

- Mixed styles exist, including rose cuts and fancy cuts

- The end use influences the decision, rings need more durability

5. Sawing and shaping

Once the plan is set, the stone is cut and shaped. Sawing removes excess rough and creates a base outline. Shaping refines symmetry and prepares the stone for final geometry. This is where craftsmanship starts to become visible, especially in symmetry and proportion.

For faceted stones, the shaping stage prepares the pavilion and crown structure. For cabochons, shaping focuses on a balanced dome, even curvature, and a flat, stable base. In both cases, the goal is consistent thickness, clean edges, and minimal stress points.

- Sawing separates rough into workable sections

- Initial shaping establishes symmetry and outline

- Thickness and weight distribution are balanced carefully

- Overheating is avoided to reduce thermal stress

6. Faceting and angle precision

Faceting is a precision craft. The cutter creates flat surfaces called facets at specific angles to reflect and refract light. The angles determine how light returns to the eye. If angles are too shallow, the stone may look dull or show windowing. If angles are too steep, the stone may look dark in the center.

Faceting also affects how large a gemstone looks for its carat weight. A stone cut too deep may weigh more but appear smaller. A well balanced cut aims for a bright face up look, good symmetry, and acceptable weight retention.

- Pavilion angles control light return and brightness

- Crown angles influence fire and scintillation

- Symmetry affects overall visual balance

- Facet junctions should meet cleanly and evenly

7. Polishing for brilliance and finish

Polishing is where the gemstone comes alive. Even a well cut stone will look flat if it is poorly polished. Polishing removes micro scratches and creates a smooth surface that reflects light cleanly. Different gemstones require different polishing compounds and lap materials.

Polishing also includes edge finishing. Sharp corners and thin points can chip easily, especially in rings. A skilled manufacturer balances crisp design with practical durability.

- Fine polishing removes haze and micro lines

- Surface luster must match the gemstone type

- Edges are refined to reduce chipping risk

- Final finish is checked under bright and diffused light

8. Calibration and matching for jewelry production

For jewelry manufacturing, gemstone calibration is essential. Calibration means the gemstones match standard size charts such as 6 by 4 or 8 by 6. Even small differences can cause setting problems, especially in mass production.

Matching is also a major part of the gemstone manufacturing process. Brands often need pairs for earrings, matched sets for necklaces, or consistent color for multiple rings. Matching requires strict sorting by color tone, saturation, clarity, and cut proportions.

- Sizes are checked with gauges and calipers

- Tolerances are controlled for reliable setting fit

- Pairs are matched by color, size, and brightness

- Sets are assembled for consistent design collections

If you want to see how gemstones fit into a broader production offering, explore the Services page for manufacturing support context.

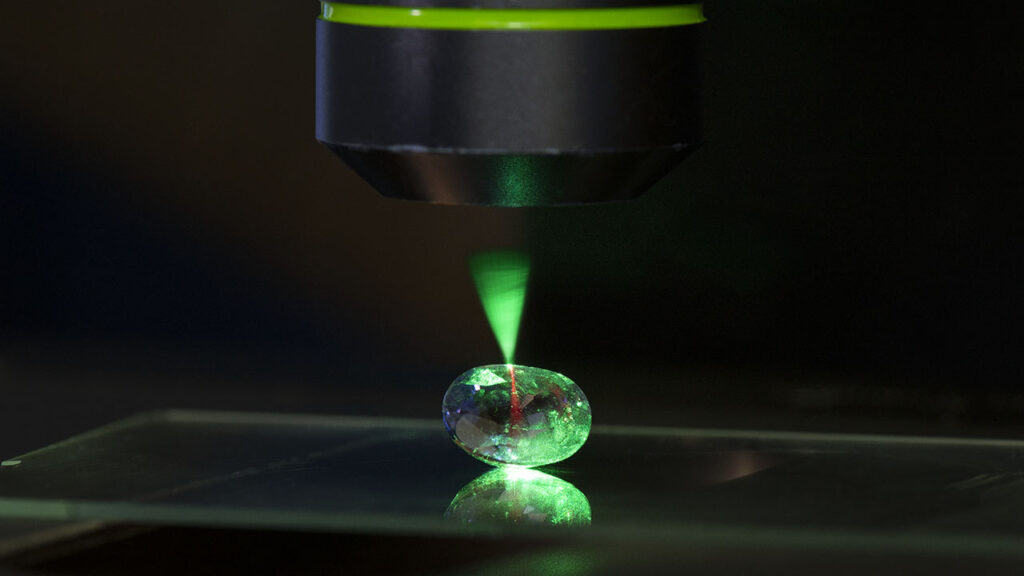

9. Treatment disclosure and stability checks

Some gemstones undergo treatments to improve color or clarity. Common examples include heat treatment and clarity enhancement. Treatment is not automatically bad, but it must be disclosed clearly because it affects value, care, and long term stability.

Manufacturers also check stability. Some stones can react to heat from jewelry repair, harsh cleaning chemicals, or sudden temperature changes. A responsible production workflow considers these factors before a gemstone reaches the customer.

- Treatments should be documented at the batch level

- Stones are evaluated for durability in intended use

- Sensitive gemstones may require special care guidance

- Disclosure supports trust and fair pricing

10. Quality control and grading

Quality control is the final gate. This stage confirms the gemstone meets the expected standards for cut, polish, symmetry, and appearance. It also ensures the gemstone is free from major chips, scratches, or structural weaknesses.

Grading can vary by supplier, but most quality checks cover clarity appearance, color consistency, and cut performance. For bulk orders, quality control ensures the entire lot is consistent rather than having a few standout stones and many weaker ones.

- Visual inspection under multiple lighting conditions

- Loupe checks for scratches, chips, and polish lines

- Symmetry and proportions are checked for balance

- Sorting into consistent grades for pricing and inventory

For more learning content that supports gemstone buying and production decisions, visit the Blog.

Common issues that lower gemstone quality

Even when a gemstone looks attractive in a photo, certain manufacturing issues can reduce real world beauty and durability. Knowing these issues helps you evaluate gemstones confidently.

- Windowing that makes the stone look see through in the center

- Extinction that creates dark dead areas with low sparkle

- Uneven symmetry that makes the stone look off balance

- Poor polish that creates dullness and surface haze

- Thin edges and sharp points that chip easily

- Color mismatch in pairs or sets used for jewelry

How to evaluate a manufacturer using process clues

If you are sourcing for a jewelry brand, you can often judge a manufacturer by how they talk about their process. Transparent suppliers describe their selection, calibration, and quality standards clearly. They can explain how they match stones, how they handle treatments, and what tolerances they maintain.

A strong sign is process consistency. When a manufacturer can deliver repeatable results across many batches, it indicates good controls and skilled workmanship. That matters whether you are buying one center stone or building an entire gemstone jewelry line.

- Ask how they match lots for consistent color and size

- Ask what inspection steps happen before shipment

- Ask how they handle calibration tolerances

- Ask what documentation they provide for treatments

- Ask what happens if stones arrive outside specification

Frequently asked questions

Timing depends on gemstone type, order size, and complexity. A single custom cut may take longer due to planning and precision. Bulk calibrated production is faster once matching rough is prepared and workflow is standardized.

Cutting is one part of manufacturing. Manufacturing includes sourcing rough, planning orientation, cutting style decisions, calibration, matching, treatment disclosure, grading, and quality control for consistent output.

Calibration ensures stones fit standard settings with minimal adjustments. This saves time, reduces setting failure risk, and improves consistency across product lines.

Yes. Cut depth and proportions change the face up size. A deep cut can retain weight but look smaller. A well balanced cut aims for brightness and a pleasing visual size.

Not always. Some treatments are stable, others can degrade with heat, chemicals, or time. That is why disclosure matters and why care guidance should match the gemstone’s treatment and sensitivity.

High quality polish looks crisp and reflective with minimal haze. Under magnification, it shows fewer polish lines and surface micro scratches. Good polish improves brilliance and overall beauty.

Matching uses multiple criteria, including size, outline, color tone, saturation, brightness, and clarity appearance. Skilled matching reduces visible differences when stones are worn together.

At minimum, stones should be checked for chips, symmetry, polish quality, calibration size accuracy, and overall appearance under more than one lighting condition. Bulk lots should also be checked for consistency across the batch.

Conclusion

The gemstone manufacturing process is a blend of skill, precision, and disciplined quality control. From rough selection and orientation planning to cutting, polishing, calibration, and grading, every step shapes the gemstone’s beauty, durability, and value.

When you understand how gemstones are made, you can buy smarter, source better for your brand, and recognize craftsmanship that lasts. Quality manufacturing is not only about shine, it is about consistency, stability, and honest disclosure.

If you want support with gemstone sourcing and production, explore the Services page for related solutions. For enquiries, connect through the Contact Us page or call +91 8769104410 to discuss gemstone manufacturing needs.