Gemstone manufacturing is no longer just about cutting and polishing a stone until it shines. Today it is about repeatable quality, calibrated sizing, reliable matching, treatment disclosure, export packaging, and consistent supply for global jewelry brands. When buyers compare gemstone manufacturing in India vs other countries, the decision usually comes down to two factors, quality control and total landed cost.

India has earned a strong position in the global gemstone supply chain because it combines skilled craftsmanship with scalable production. At the same time, other countries offer unique advantages such as origin based branding, premium niche craftsmanship, or access to specific rough sources. The smartest sourcing strategy is not always choosing one country. It is choosing the right manufacturing location for the right gemstone category, design requirement, and customer price point.

If you want to review product categories typically sourced for jewelry production, explore the Gemstones collection to understand how gemstone selection connects with manufacturing outcomes.

What quality means in gemstone manufacturing today

Quality in gemstone manufacturing is not a single feature. A gemstone can have great color yet fail in jewelry production because it is not calibrated, or it chips because edges are too thin. For global buyers, quality means the stone performs well in real world settings and arrives consistent across repeat orders.

In a practical sense, quality is a combination of cut performance, polish finish, symmetry, durability choices, matching accuracy, and honest disclosure. When you compare India with other manufacturing hubs, look at which countries consistently deliver these factors at the grade level you need.

Key quality indicators buyers should evaluate include the following.

- Cut performance that avoids windowing and dark zones

- Clean polish with minimal haze and surface lines

- Consistent symmetry and shape across parcels

- Calibration accuracy for standard settings

- Matching for pairs, sets, and shade lots

- Durable edge thickness for rings and daily wear

- Treatment disclosure and stable enhancements

- Export safe packing and parcel integrity

For a clearer view of how professional production workflows are structured, you can review the Process page and compare it with the checkpoints listed in this article.

Why India is a major gemstone manufacturing hub

India is known for strong lapidary skill, large scale manufacturing capacity, and competitive cost structures. In many gemstone categories, India can deliver a wide range of grades, from commercial goods for fashion jewelry to finer calibrated stones for retail collections.

One important advantage is ecosystem depth. Many regions in India have specialized clusters for cutting, polishing, bead making, cabochons, and jewelry production. This makes it easier to scale orders, match sets, and maintain consistent supply across seasons, especially when a supplier has strong process control.

If your sourcing is connected to jewelry production, you may also find the Jewelry manufacturing process helpful because gemstone output and jewelry setting requirements must align.

India vs other countries, the most important comparison factors

Comparing gemstone manufacturing in India vs other countries should not be reduced to a simple cheaper vs expensive idea. The best comparison looks at total value, which includes price, consistency, lead time, defect rates, reorder reliability, and brand positioning.

1. Craftsmanship and cutting expertise

India has strong cutting expertise across many stone types and shapes. Other countries may specialize more narrowly, for example premium niche hand cutting in smaller studios or origin focused artisanal work.

In many commercial and mid premium categories, India can offer excellent make, especially when the manufacturer uses strict calibration and quality control. In ultra premium custom cutting, some buyers prefer boutique cutters in markets known for high end precision cutting, but those options often come with higher pricing and lower scalability.

2. Consistency at scale

This is where India often performs strongly. Many international brands need repeatable parcels, matching, and reliable delivery schedules. Some smaller markets can produce stunning stones but struggle to scale consistent lots without noticeable variation.

Consistency is a process outcome. It depends on how rough is selected, how cuts are planned, how matching is done, and how strict inspection gates are. Manufacturers that document and repeat their workflow deliver better results, regardless of country.

3. Cost structure and total landed cost

India typically offers competitive manufacturing costs due to skilled labor availability, mature supply chains, and scalable operations. Other countries may have higher labor costs, smaller production capacity, or higher overhead, which increases unit prices.

However, low unit cost is not the same as low total cost. If stones arrive off size, inconsistent, or damaged, your total cost rises through setting delays, returns, and customer dissatisfaction. When comparing countries, measure total landed cost, not only the per carat rate.

4. Lead times and communication

India can be very fast for calibrated and repeated goods when the supply chain is stable. Other markets may offer faster turnaround for one off custom work, depending on workload and proximity.

Communication quality is supplier specific, but it matters. Clear specs, sample approvals, and photo video verification reduce mistakes in any country.

5. Treatment disclosure and transparency

Treatment is common in the global gemstone industry. The key issue is disclosure, stability, and care guidance. India has many reputable suppliers who disclose treatments properly, but buyers should still request clear documentation and invoice descriptions.

Some buyers choose certain markets for stronger brand perception around natural origin or specific mining provenance. That is a marketing choice, not always a quality difference.

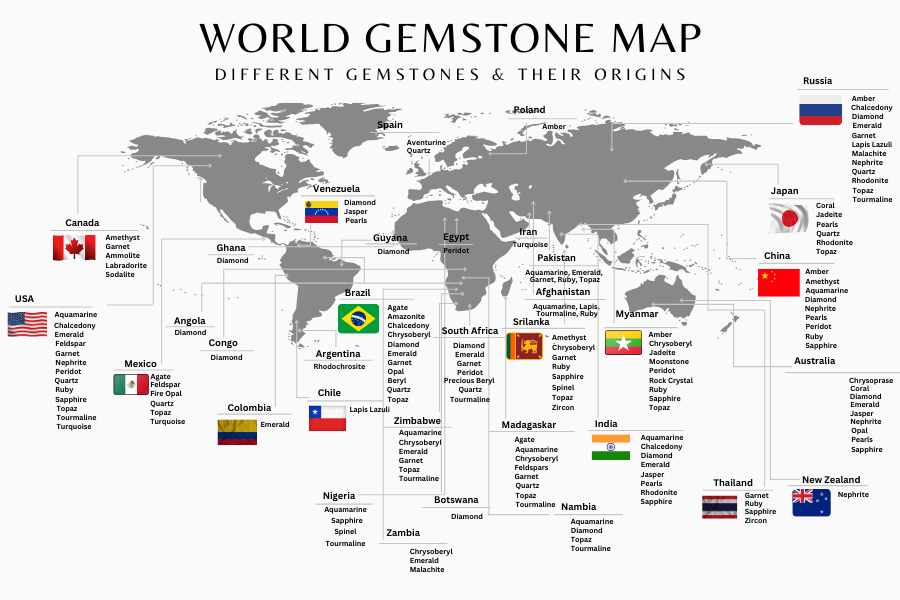

Country by country snapshot, strengths and tradeoffs

Each region has a different advantage. Use this as a directional guide rather than a rule, because supplier quality varies widely.

- India, strong scale, good value, wide gemstone range, reliable calibrated supply when processes are strict

- Thailand, strong colored gemstone trading and experience, good access to certain categories, quality varies by supplier tier

- Sri Lanka, known for sapphire and certain natural stones, good origin story, higher cost for top material and limited scale for some sizes

- China, strong manufacturing scale in many categories, can be competitive on cost, quality control depends heavily on factory standards

- Brazil, strong access to certain rough and unique materials, cutting quality varies, export and consistency can depend on vendor

- United States and parts of Europe, premium custom cutting and boutique craftsmanship, typically higher cost and lower volume

For buyers who want educational context on gemstone categories and how they affect pricing expectations, the guide on Precious vs semi precious gemstones supports better decision making.

When India is the best choice

India is often the best option when you need consistent supply, good finishing, and competitive cost for production jewelry. This includes brands building repeat collections, wholesalers requiring matched parcels, and manufacturers needing calibration to fit standard settings.

India is also a strong choice when your product line includes multiple gemstone types. A good supplier can help you consolidate sourcing rather than managing many small vendors across multiple countries.

Common situations where India performs especially well include these.

- Calibrated stones for rings, earrings, and repeat settings

- Matching pairs and sets across consistent color ranges

- Bulk parcels for wholesale and retail lines

- Private label jewelry production requiring steady supply

- Mixed gemstone catalogs where consolidation simplifies sourcing

If you are evaluating a supplier based on capability rather than location alone, browsing the Services page can help you understand the kinds of support a manufacturing partner can offer.

When other countries may be a better fit

Other countries may be a better fit when your brand relies heavily on origin storytelling, when you need specific mining provenance, or when you want a boutique custom cut that prioritizes artistry over scalable repeatability.

You might also source outside India when a specific gemstone is strongly associated with a region and your customers pay a premium for that association. This is common in certain sapphire markets, some tourmaline categories, and niche collector stones.

Other countries can also be useful for specialty materials or very small batch collections where the maker’s style is a core part of your brand identity.

How to compare suppliers fairly across countries

A fair comparison uses the same specification and evaluation method for each supplier. Many sourcing problems happen because the buyer compares a premium grade sample from one country with a commercial grade sample from another.

Use a consistent checklist and ask for the same proof points.

- Request the same size, shape, grade, and shade range in samples

- Verify calibration tolerances using measurements, not only photos

- Ask for matching rules for sets and pairs

- Confirm polish standards and inspection under multiple lighting conditions

- Request disclosure of treatments and care limitations

- Evaluate packing methods for export safety

- Test reorder consistency by placing a small repeat order

A helpful way to build your internal selection standards is to document what you will accept as commercial grade, mid grade, and premium grade for each gemstone type. That way, supplier conversations become clearer and results become repeatable.

For more sourcing and manufacturing insights, you can explore the Blog for related guides that support buying decisions.

Cost comparison without getting trapped by the lowest quote

A low quote can be attractive, but it is rarely the whole story. Your real cost includes yield losses, setting time, returns, customer service workload, and reputation risk. A slightly higher unit price can be cheaper overall if it reduces defects and improves reorder consistency.

When comparing India vs other countries, ask suppliers to quote based on identical specs and include packaging and delivery terms clearly. If possible, track defects per batch and compare suppliers using data instead of impressions.

Cost drivers that affect your final numbers include the following.

- Grade and clarity appearance, which affects yield and selection cost

- Calibration tolerance, tighter tolerance often costs more

- Matching intensity, strict matching raises labor time

- Cutting style, fancy shapes can require more time

- Order size and repeatability, stable repeats can reduce cost

- Packaging quality, better packing reduces damage losses

- Documentation and treatment disclosure, adds professional overhead

FAQs

Often it is more cost effective, but not always. Total cost depends on grade, matching, calibration, defect rates, and reorder reliability. A higher priced supplier can be cheaper overall if quality is more consistent.

No. Process discipline and craftsmanship decide quality. Country influences ecosystem strengths, but an excellent supplier can exist in many regions, and a weak supplier can exist in a major hub.

Ask about calibration tolerances, matching criteria, inspection steps, treatment disclosure, and how they handle reorders. Request real lot photos and sample approval before bulk orders.

Treatments are common globally and vary more by gemstone type than by country. The key is disclosure, stability, and correct care guidance, not the location alone.

Jaipur is known for lapidary skill and scalable cutting and polishing. It supports calibrated production, matching, and consistent supply for many colored gemstone categories.

Not always. Certification is valuable for higher value stones, for stones with origin claims, and for categories where treatments strongly affect price. For commercial goods, clear specifications and a trustworthy supplier can be sufficient.

Start with samples, define specs clearly, approve the exact lot, and begin with a small batch order. Track defect rates and consistency before scaling.

Many successful brands use a hybrid strategy. They source production and calibrated goods from a scalable hub, and source select hero stones from origin focused or boutique markets for premium storytelling.

Conclusion

Comparing gemstone manufacturing in India vs other countries becomes simple when you focus on the outcomes that matter, consistent beauty, reliable sizing, honest disclosure, and repeatable supply. India often delivers strong value and scale, especially for calibrated and matched goods used in production jewelry, while other countries can shine for origin branding, specialty materials, and boutique cutting.

The best sourcing decision is the one that matches your customer expectations and your product model. Measure total landed cost, evaluate process controls, and choose partners that can deliver consistency, not just a low quote.

If you want support with sourcing, manufacturing, or bulk supply, explore the Services page for related solutions. For enquiries, connect through the Contact Us page on the website, or call +91 8769104410 to discuss your gemstone requirements.